TECTRAN: Rolling to Success In the Automobile Industry

• TECTRAN: Rolling to Success In the Automobile Industry

With the high-scale advancements in the automobile industry, the role of technology has redefined the limits of human innovation.

From developing fuel-efficient and powerful engines to making the vehicle more aerodynamic and agile, the level of innovations is stupendous.

TECTRAN CORPORATION —a wheel manufacturer serving customers across US and Europe with innovative and custom-designed aluminum alloy wheels.

The company develops unique and lightweight designs that improve the aesthetics and performance of the vehicles.

• Building on Innovation and Excellence

The alloy wheel market has been gaining a lot of prominence since 2010, with the industry expected to grow by USD 0.52 billion during 2020-2024.

The reason for this being–more and more customers are now interested in improving the appearance and performance of their cars.

Over traditional steel wheels,aluminum alloy wheels are lightweight which ensures better acceleration, braking, and fuel economy.

.jpg)

Flow Forming Technology. Image courtesy of TECTRAN CORPORATION.

TECTRAN serves wheel companies located across the USA and Europe with innovation and excellent service.

The company’s best-selling product is the T800 wheel model, renowned for its unique design and excellent performance.

• Outperforming with distinction

TECTRAN offers a wide range of customizations and unique features to its customers, which puts them ahead of their competition.

The lightweight wheels improve the fuel economy and ride quality of vehicles.

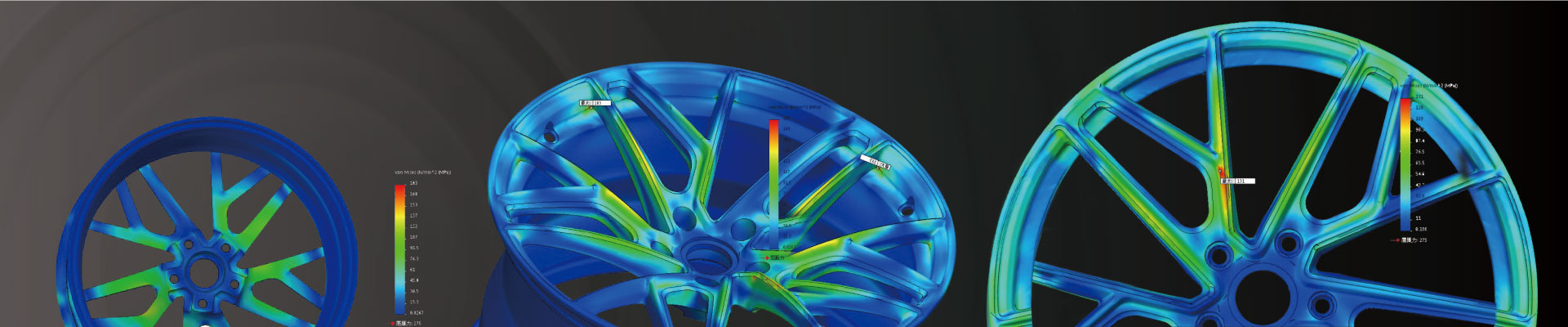

However, the manufacturing process is nowhere a walk-in-the-park. TECTRAN uses 3D FEM analysis on each design before tooling.

This ensures wheels undergo a wide-range of strength tests to check impact, bending fatigue, and radial fatigue of a design.

.jpg)

FEM Analysis. Image courtesy of TECTRAN CORPORATION.

Only the designs that pass these stringent tests are approved and used for mass production. In addition, the company also provides D.O.T and TUV test standards on request.

• Latest offerings and designs

TECTRAN offers three main types of aluminum alloy wheels:

• Cast aluminum wheels:

It involves molten aluminum injected into a pressurized cast.

TECTRAN uses A356.2 aluminum alloy to manufacture these wheels, making them affordable for a broad market.

• Flow forged wheels:

The process involves a wheel cast made from aluminum with steel rollers to stretch the barrel to its final size.

The casting material is A356.2 alloy, but the flow forming process makes the rim thinner and stronger. This type of wheels is ideally used by performance car enthusiasts.

• Fully forged wheels:

It involves solid T6061 aluminum alloy heated to extreme temperatures with pressurized machines to shape the wheel.

This type of wheels is commonly used by professional rally teams and competitions.

While both flow forged and fully forged wheels are renowned for their tensile strength, durability and reliability -- fully forged wheels are purely custom made, which makes them more costly and highly distinctive designs.

• Gearing up for the future

Unlike other businesses heavily affected by the COVID-19 pandemic, TECTRAN and its customers have remained strong and steadfast. TECTRAN already has a strong presence in the industry and predicts that the demand for their products will increase significantly as the popularity of aluminum alloy wheels increases.

TECTRAN’s next goal is to expand its reach to the US market. In the past, US automakers imported parts mostly from China but in light of the US-China trade war, TECTRAN aims to fill that vacuum. Combined with the company's continuous output of high-quality auto parts, the company has a strong foundation for growth.

Source: TECTRAN CORPORATION